The 10 Best Gas Detectors

This wiki has been updated 42 times since it was first published in October of 2015. Whether you are a service engineer or a homeowner looking to protect your family from explosive and dangerous emissions, one of these gas detectors will sound the alarm to help keep any premises safe. Grab one designed to identify the gases you are most concerned with, such as carbon monoxide, methane, butane, or propane. We've ranked them here by their sensitivity, durability, and ease of use. When users buy our independently chosen editorial selections, we may earn commissions to help fund the Wiki.

Editor's Notes

March 02, 2021:

While the majority of our previous picks were still available and good choices for this category, it still wound up being quite a busy round of updates, as we were able to identify a number of excellent options to add to our list. We also removed the Amprobe GSD600 due to availability issues, and eliminated the General Tools & Instruments 2000A due to lack of favorable user reviews.

We added two new choices from Forensics Detectors — namely the Forensics Detectors YR-G6Y8-HA75 and Forensics Detectors QX-CDBY-A03G. Both of these choices feature color displays and rugged builds that I’m sure will appeal to many technicians. However, while the latter employs a single sensor hanging from a gooseneck, the former has four electrochemical units built right into its body, which makes it possible to do more monitoring than its counterpart. It also offers data-logging and graphing functions, but none of this added utility comes cheap, and the disparity between prices for these two will likely make it easy for most users to make their minds up.

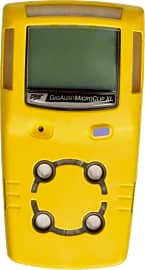

The BW Technologies MicroClip XL 4 is another top-end, four-sensor choice we included – from one of HVAC monster Honeywell’s child companies – and while it certainly looks to be a very capable and durable instrument, the user experience offered by its interface looks to be clearly inferior to the unit from Forensic Detectors that we were just discussing. Naturally, some tech-resistant technicians will prefer the brand-name recognition and simple, single-button control offered by the MicroClip XL4, but unfortunately, this won’t be a case of simplicity saving you some money.

For another mid-range option for professionals on a budget, we also incorporated the Klein Tools ET120 to our list, which costs considerably more than some consumer-level models, but can save you some serious cash when compared to the elite metering gear in this category.

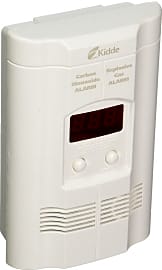

And, our last new addition was the Seesii Smart US27LSXJX1164MG. This choice joins the Kidde Nighthawk COEG-3 on our list as a non-portable option that’s likely to be best suited for permanent installation in residential locations. In fact, we put some serious thought into axing the COEG-3 altogether, in light of our new addition offering app connectivity for virtually the same cost, and looking so much more stylish doing it. However, considering how high the stakes are here, we didn’t like that our new pick from Seesii didn’t have a backup battery, so we retained the COEG-3 for anybody who wants a dead-easy, set-it-and-forget-it, plug-in model. For more options like that, consult our list of carbon monoxide detectors.

May 13, 2019:

Despite its rugged build and reliable readings, we felt that the MSA model previously at number one was just a little too expensive when compared to the rest of the field, and the features that increased its price point were ones that most users could probably do without. Sure, that housing protects the device considerably, and it has a nice display, but if you're marginally careful with your equipment and you don't need a fancy readout, you can save a bit of money on either of the equally high-performance models at numbers one and two and not miss out.

We did add a new model to our list, in the form of the Techamor Y201. It's definitely a budget option with a build quality that might not survive more than a drop or two, but for the user who only needs to detect gas once in a while, it's more than sufficient.

Special Honors

Industrial Scientific This company offers a range of solutions to help stay on top of 15 dangerous gases, including many instruments that are capable of monitoring multiple substances. All of their equipment is backed by a lifetime guarantee. indsci.com

Fluke Ti450 SF6 Gas Detector This slick instrument sports a comfortable pistol-grip design. Using a color screen and an infrared camera, it can help you identify sulfur hexafluoride leaks without shutting down your equipment. Although it has been discontinued by the company, it still appears to be available through third-party sellers. fluke.com

Understanding The Underlying Technology

This change in light determines both the presence of a gas and its type.

Whether you're a mechanical engineer, construction worker, school official, or business owner, or you want to keep your family safe from harmful and toxic emissions in your home, a gas detector can mean the difference between safety and potential disasters.

The gas detector is a portable or fixed device designed to measure and indicate the concentration of toxic emissions in the surrounding environment in order to prevent explosions or harmful exposure. Most detectors produce an audible or visual indicator, such as an alarm or series of lights, to signify high levels of gases in a particular area. While older detectors can only produce alerts for one type of gas, modern detectors are multifunctional and capable of detecting several gases at once.

The devices can be used as standalone units to monitor a small working area or they can be linked together to create an entire protection system, depending on the nature of the circumstances and the size of the detection area. Although it might seem that a gas detector's operation is complicated, the fundamental concept underlying its purpose is relatively simple to comprehend. Because it is designed to measure a specified concentration of a harmful gas, its internal sensor technology serves as the reference point (or scale) for determining normal levels versus dangerous ones. When the detector's sensor surpasses a pre-set level, an alarm is triggered to alert the user of potential danger.

Detectors are categorized by the types of gases they detect and the type of sensor technology they use. Both electrochemical and metal oxide semiconductor sensors will detect toxic gases, while catalytic bead and infrared sensors are designed to detect combustible gases. Electrochemical detectors operate via the diffusion of gases through a porous membrane to an electrode where they undergo redox. The degree of electrical current produced by this chemical reaction is determined by how much of a particular gas has been oxidized at the electrode, which ultimately indicates the level of gas concentration. Electrochemical detectors are used to detect carbon monoxide, chlorine and nitrogen oxides. Metal oxide semiconductor (MOS) sensors also detect carbon monoxide and function using a gas-sensitive film that is composed of either tin or tungsten oxides. This film reacts when a certain level of toxic gas is present, triggering the device to alert or warn the user.

Metal oxide sensors are efficient due to their ability to operate in low-humidity ranges. Catalytic sensors detect combustible gases and are constructed from a platinum-treated wire coil. They function via catalytic oxidation, which is really a fancy way of describing the process by which a chemical helps to speed up the process of a reaction without changing its own structure. When a combustible gas comes into contact with the catalytic surface, it is oxidized, while the wiring resistance is changed at the same time through the release of heat. A bridge circuit, like a Wheatstone bridge, is then used to indicate this change in resistance. Infrared sensors operate through the use of transmitters (light sources) and receivers (light detectors), whereby the presence of a gas interferes with the power of a light transmission between the two. This change in light determines both the presence of a gas and its type.

Determining The Best Detection

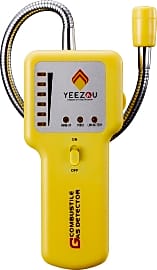

The type of business, the size of the environment, and the gases that are present are all driving forces behind one's decision to invest in a gas detection system. For example, if you work in a large industrial complex, a welding shop, or any environment with combustible gases around all the time, then fixed catalytic or infrared detectors will certainly come in handy. The same can be said for a fixed detector if you're a homeowner with the need for an easy-to-read display to alert you and your family to the presence of toxic gases. The ability to detect multiple gases is also important, particularly methane and propane.

Portable detectors are beneficial for use in tight spaces and when having to work underground (e.g. in subway systems between station platforms), as they can be battery-operated and easily attached to a worker's tool belt. If you're taking tools with you on the job, having one with a compact design makes it easy to transport and to store.

Testing and calibrating one's chosen gas detector is an important consideration for maintaining safety and confidence that the device (whether it's fixed or portable) is working properly, accurately, and that it will alert you when the need arises.

A Brief History Of Gas Detectors

Prior to the development of electrical sensor technology, the earliest detection methods used around the time of the Industrial Revolution included wet blankets and long wicks lit on fire to detect dangerous pockets of methane gas located in underground coal mines. The dangers of methane come from the fact that it cannot be seen or smelled and that it can appear naturally from underground.

A flame was always started on the middle line in a fresh air environment.

Considering that coal is a fossil fuel still in use to this day, one can understand the dangers first employed to harness its energy using primitive mining techniques. After this detection method proved ineffective, miners then used canaries in coal mines to assist in their detection efforts due to the bird's loud chirp and similarities to the part of the human nervous system that controls breathing. Miners believed that when a canary wasn't doing well, it would begin to shake its cage, alerting them that it wasn't safe to remain inside.

Following use of the canary, the flame light was the next form of gas detection. The flame light was encapsulated inside a shell with an outer glass piece featuring three horizontal line incisions running along its surface. A flame was always started on the middle line in a fresh air environment. If the flame lowered itself toward the bottom line, a miner would know they were in an oxygen-deficient environment. If the flame rose toward the top line, it would signify an oxygen-enriched environment with the possibility for the presence of methane.

The first gas monitor was a valved device showing the level of methane present in the atmosphere and was detected through a sensor called the catalytic diffusion sensor. This sensor would burn the gas inside it, but never allowed the burning process to occur outside of the sensor.

The first electronic household carbon monoxide detectors were developed in the 1980s. Since that time, many electronic devices (fixed and portable) have been developed for a variety of applications to detect, monitor, and alert people to potential gas leaks. This includes the presence of gas detectors inside modern consumer automobiles.