The 10 Best Drill Bit Sets

This wiki has been updated 40 times since it was first published in October of 2015. Whether you are a professional contractor or an occasional home DIYer, you'll find one of these drill bit sets perfect for your next project. We've included a range of options, from pocket-sized kits with all the most commonly needed sizes to those that come with anything you could possibly want for metal, plastic, wood, or masonry, so you'll always have the right tool for the job. When users buy our independently chosen editorial picks, we may earn commissions to help fund the Wiki.

Editor's Notes

December 17, 2020:

For this update, we removed the Irwin Tools 3018002, a relatively quality set, but one that lacked the strength and durability to justify its high price. We also removed the Neiko 10197A from our list because it only included five step-bits, which we felt made it a bit too specialized for our collection.

We also removed the Portamate PM-1350 set. Though it included an impressive 300 pieces, the components were just not durable enough to earn a spot on our list. Plus, another entry, the VonHaus 15/384US has nearly as many pieces, at a much lower price.

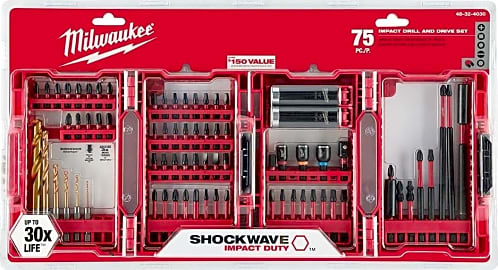

We also added three Milwaukee brand options to our collection. Milwaukee’s “shockwave” bits are designed to be incredibly durable, and can withstand the extreme torque stress that comes from constant use. If you’re a professional woodworker or just do a lot of DIY projects, I would highly recommend choosing one of the Milwaukee sets here. For occasional use, our other drilling options, like the Irwin Tools 316015 or the bits that come with the Makita T-01725 should suffice just fine.

If you plan on creating especially large holes, the options above might not provide the bits you need. These spade bit sets might be a better fit, and some supply bits up to 1 1/2-inches wide. Looking to create even bigger holes? A hole saw set will equip you to power through wood and metal, leaving openings up to 5-inches wide.

May 02, 2019:

If you don't have the right tool for the job, at best your work will be inefficient, and at worst, it may even be dangerous. To ensure you are always working with the correct tool, we have compiled a list of the best drill sets. If you use your drills daily, then a contractor-quality set is a must. Some examples of these on our list include the Irwin Tools 3018002 and Irwin Tools 316015, both of which are crafted with cobalt for maximum durability, as well as the DeWalt DW2587, which features black-oxide coated bits that are highly corrosion resistant. If you need to bore holes in metal, there is no better option than the Neiko 10197A. It may look like it only includes a few pieces, but each one is capable of a variety of different holes sizes, giving you 50 options in total. If you don't already have very many bits, you will be well-served by the VonHaus 15/384US or Portamate PM-1350, both of which come with more than 200 pieces. For home DIYers who don't want to spend a lot of money and aren't going to be subjecting their tools to a lot of stress, we have included the Black & Decker BDA91109.

The Surprisingly Complex World Of Drill Bits

For every job requiring drilling, you can find a purpose-built drill bit.

The drill is one of the most ubiquitous tools used today, found on every job site, in every auto body shop and repair store, and in almost every home across the country. Early variations of the drill involving a rotating rock or stick have been identified dating back many tens of thousands of years. Mechanically advanced drills driven by hand-operated bows date back at least ten thousand years. Improvements to the drill's force application mechanism and ever more advanced variations of drill tips continued throughout the common era, with perhaps the greatest advancement coming in the late 19th Century with the advent of the first electric drill.

Designed by Australian inventor Arthur James Arnot, the earliest electric drill was large and cumbersome, but it was effective. The year 1895, a mere half decade later, saw the development of the first truly portable electric drill. And when a trigger-operated, pistol grip style electric drill was released by the company Black & Decker in 1917, the basic design of the ideal electric drill had been discovered. Ever improved technology would add more power and would reduce the size of the electric drill over the years (and in the 1960s the battery powered drill would also enter the fray), but for all intents and purposes, the only remaining advancements to be enjoyed by the drill would be in the form of advanced, enhanced drill bits.

For every job requiring drilling, you can find a purpose-built drill bit. That's as true for drilling through basic wooden boards as it is for drilling through solid sheets of glass. There are drill bits designed for fitting doorknobs into doors and there are drill bits intended for use only in softer metals, like copper or brass. You can find a drill bit designed specifically for making holes smaller than one millimeter and, at the extreme opposite end of the spectrum, there are bits that bore holes many feet across and many thousands of feet down into the earth for the purposes of oil and gas extraction.

Most of us, however, will find our drilling needs met with a much more basic set of bits. But one should still take care to choose the right set; doing so can help to save you time and keep you safe.

Choosing The Right Drill Bit Set For You

For most people simply looking for help making holes for hanging picture frames, repairing damaged furniture, or completing a few fun DIY projects around the home, a set of general purpose drill bits makes perfect sense. As long as you will only be drilling into wood, drywall, or composite materials like MDF (medium density fiberboard, a material commonly used in lower-cost shelving and furniture), then a basic set of twist drill bits, those with a spiral shape along their shaft, will get the job done with aplomb.

Try to use a twist drill bit on a thicker piece of metal, and you will waste your afternoon, and likely ruin the bit at the same time.

For more complex projects involving harder materials, you absolutely must use a specialized drill bit. Try to send a spiral drill bit into a piece of tile, for example, and you will crack the tile into pieces. Try to use a twist drill bit on a thicker piece of metal, and you will waste your afternoon, and likely ruin the bit at the same time.

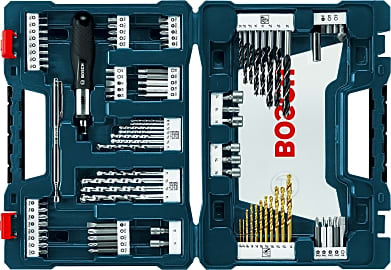

While a set containing lots of different varieties of drills bit might seem like a great idea, if you're never going to drill through sheet metal or glass, there's no need to look for bits capable of so doing. Instead buy a set that meets your current needs with bits in a range of sizes (starting with a narrow bit and working a hole wider and wider is the best way to go, after all) and then consider adding a single specialty bit later if needed for a specific purpose.

Proper Use Of Your Drill Bits

You need to accept from the outset that, eventually, you will be replacing your drill bits. Even the finest drill bit in the world -- even that bit made of tungsten carbide intended for meticulous use with circuit boards or one coated with titanium nitride and designed to resist high heat -- will eventually crack, chip, or simply wear down beyond the point at which it is effective. The very nature of a drill bit's job means constant, heavy wear and tear every time it is being used.

So don't think of drill bit maintenance as preservation, but rather as delaying the inevitable and getting the best work done before it's time for a new bit (or set of bits). The simplest and best way to make the most of your drill bits is to only use them with their specified material. Not only will a bit intended for drilling into masonry do a poor job of putting a hole in piece of metal, but such use will also effect the bit's crisp wedge shape over time. A cobalt bit might stand up to the heat of drilling into stainless steel, but if there is too much pressure exerted on the bit as it bores deep into hardwood, it may well snap in half, wasting time and potentially presenting a safety hazard.

Also keep in mind that it's seldom necessary (and often inadvisable) to run a drill at its top speed. Using a moderate rotation allows a drill bit to pull out the material it has already loosened, sending bits of wood, metal shavings, or other materials away from the hole instead of pointlessly bearing down on the swarf.