The 10 Best Bench Vises

This wiki has been updated 37 times since it was first published in September of 2015. When stability is integral to a successful project, a bench vise may be the answer. DIY enthusiasts and professional contractors alike will find the perfect option for their next job from our comprehensive selection. Able to attach to many tables and handle a wide range of tasks from big to small, these mighty grippers will ensure a safe and solid hold on almost any material. When users buy our independently chosen editorial selections, we may earn commissions to help fund the Wiki.

Editor's Notes

February 26, 2021:

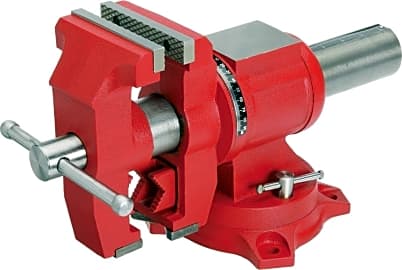

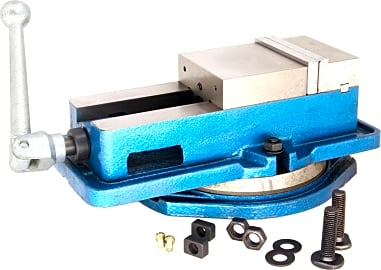

One of the most versatile tools in the woodworking, metalworking, and other manufacturing industries, a bench vise is designed to attach directly to the workbench to hold the workpiece during operations such as sawing, planing, and drilling. They come in a range of shapes and sizes and include useful features such as 360-degree swiveling, built-in anvils, replaceable jaws, and specialist clamps for pipes and other round materials. In this update, we researched all of our recommendations and found them to be up-to-date and high-quality options, therefore we made no changes to the ranking at this time.

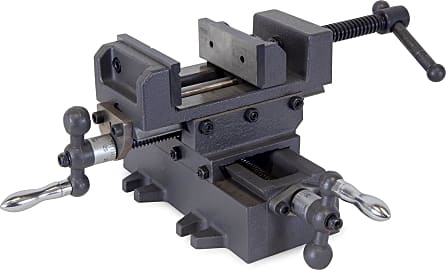

For those needing a vise for use with a drill press, the Hardware Factory 15979 is a compact option with heavy-duty jaws made from 80,000 PSI ductile iron. Similarly, the larger Wen 413CV features a cross-style design that allows horizontal and vertical adjustment, allowing for precise material placement. For maximum versatility, a vise with a rotating head, such as the Grizzly G7062 or the Yost 750-DI allows workpieces to be positioned at any angle, and both feature built-in pipe clamps for holding round and square stock. If you would prefer not to have a vise permanently fixed in one position then the Irwin 226303ZR is a lightweight and portable option that mounts to a bench using a clamp mechanism that can be fastened on tables up to 2 inches thick. Finally, the Panavise 301 is designed for intricate work and features a multi-angle head with three planes of movement, making it ideal for jewelry and model makers.

December 11, 2019:

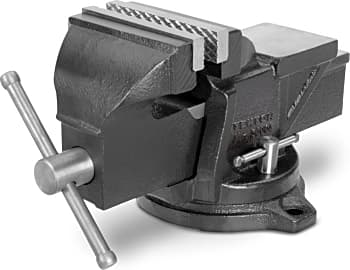

Removed the Yost LV-4 in favor of the Wilton 746. There are several things that make this Wilton more appealing than the Yost. First off, the Wilton has a more stout base and a denser overall construction which will lead to greater stability. It also has replaceable pipe jaws in the throat whereas the Yost doesn't so when they wear out, it'll lose that capability. Finally, the Wilton has an enclosed acme rod as opposed to the exposed rod on the Yost which will allow dirt to contaminate the thread grease and roughen up its movement.

The Wilton 11104 takes the top spot because it has a similar robust construction to the 746 but is incredibly affordable. It has less features than the 746 but it'll handle most of the same tasks and also take a lot of punishment.

Always make sure you tighten the vise enough to secure the workpiece to avoid injury. Never hold pressure vessels using a bench vise.

Special Honors

Bessey With over 130 years of experience in precision steel and tool manufacturing, Bessy is a market leader in metal clamping and cutting technology. Their vises range from heavy-duty industrial models to light-duty fully adjustable ones, and are made using high-quality materials and components. bessey.de

Micro-Mark Jewelry and model makers alike will appreciate the range of mini hand tools on offer at Micro-Mark. Their versatile selection of machinist, toolmakers, and milling vises undergo the highest level of high-quality testing, and come in a variety of sizes, for clamping the smallest of parts and carrying out intricate work. micromark.com

What To Do With A Bench Vise

If you run a construction company or wood-working shop, you likely worry constantly about your employee's safety.

If you run a construction company or wood-working shop, you likely worry constantly about your employee's safety. Workers in these environments face risks like hearing loss, head trauma, and life-threatening cuts. A bench vise can at least reduce the risk of the latter. This tool holds a workpiece, like a board of wood or sheet of metal, stationary while a person does things like sawing, drilling or boring it. As the tool's name implies, it usually attaches to a work bench, and typically sits flush with the work surface. The amount of force many power tools apply to a workpiece can be so powerful, that a human hand alone cannot hold it in place.

Anyone who has a workshop of any kind will find that a bench vise has plenty of uses. If you are completing a project in which the pieces must be held together by glue, a bench vise can hold them in place while the glue dries properly. Cutting into lumber with an electric chainsaw is much easier when the wood is held in place by a bench vise, and it will ensure the straightest edges. A bench vise is also essential when doing any sort of drilling, especially if you need your holes to be precise in their location and size.

There is no question that anyone who cuts materials for commercial use cannot afford to be without a bench vise. In many applications, precision cuts are necessary. Making an improper cut time and again can become costly very quickly. One may have to start all over again with a brand new workpiece. If working with expensive materials, this can add up to a significant cost on a single job. Bench vises reduce the chances of making improper cuts, not only saving money, but time too.

What To Look For In A Bench Vise

If you need to clamp onto large pieces of wood, look for a quality metal dog in your vise. Square dogs tend to provide the greatest grip. Vises with countersunk holes are the easiest to attach to a work bench, as are those made from a lightweight material like aluminum. Just make sure the rods stay tight so your vise doesn't move while you're working as contact with equipment is one of the top causes of injuries on construction sites.

The heftier vises have double lockdowns to ensure they stay in place under the most strenuous jobs.

If you work with delicate materials, or simply want a finished product that has very little markings on it, consider a bench vise with rubber covering on its clamps. This will reduce the amount of scuffs and scratches on your materials. Depending on your needs, you may either want a small, portable bench vise, or you may need a heavy duty, more permanent one. Some can assert thousands of pounds of pressure and have impressive tensile strength so they will not break under extreme tension. The heftier vises have double lockdowns to ensure they stay in place under the most strenuous jobs. Just make sure, especially with the heavier vises, that the u-channel glides easily.

If you work with materials that create very little surface friction, like metal, make sure your vise clamps have non-slip markings to grip onto them. This will look slightly like the tread on the bottom of a boot. Those who work outdoors or in humid climates should look for a bench vise with powder coating to prevent rusting, which can happen to materials one wouldn't even expect, like stainless steel.

The History Of The Bench Vise

It's a mystery who invented the very first form of the bench vise, but before it came to be, workers would simply clamp items together through the use of a wedge and hammer. The first version of the bench vise came about in the middle ages and used clamps with threads. These held workpieces vertically, though, and would tend to tilt. The year 1750 saw the creation of the parallel vice. On this tool, the jaws moved on adjustable horizontal slots, which held materials in place much better than the previous model. But it is most likely that the first patents for such a tool didn't exist until the early 1900s.

Many of them would break if one applied to much tension, so they were useless for heavy duty jobs.

The English began making cast iron vises in 1830, but because air bubbles would form during the pouring of the liquid iron, these models could be quite frail. Many of them would break if one applied to much tension, so they were useless for heavy duty jobs. This ushered in the need for vises made from forged steel.

In 1925, German inventor Josef Heuer created the drop-forge vise, with its innovative dual-prism guide track. Brockhaus Heuer is still one of the leading manufacturers of bench vises. With their first vise, the Heuer Prism, seeing much success, the company's team set to work creating a new vise to piggyback on the popularity of their first one. And so came to be the Heuer Front, a vise that opened in the front, towards the worker.