The 7 Best Nail Pullers

This wiki has been updated 41 times since it was first published in January of 2017. Just when you thought you would never get that misplaced fastener out of the baseboard, shelf, or door frame on which you're working, you found our list of these nail pullers. Armed with one of these, no brad or ring shank will stay stuck for long, no matter how deep it has been hammered in. We based our selections on durability, functionality, and price. When users buy our independently chosen editorial selections, we may earn commissions to help fund the Wiki.

Editor's Notes

October 03, 2019:

Removed the Air Locker AP700 Professional Punch because of concerns that it did not fit the category. Added the Vaughan & Bushnell 4250, the Estwing PC210G, and the Stiletto TICLW12.

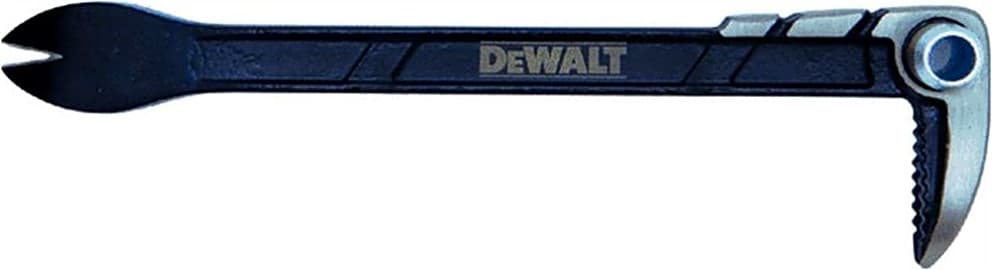

In terms of quality, the Stiletto is the clear best. The titanium and cut-out design make it extremely light but also very tough. As a bonus, it comes with a small tube on the head that can be used to expose hidden nails. The Estwing is among the favorites for construction workers doing demolition and framing. It is very cheap and very robustly made. The rubber handle does eventually tear for one reason or another but the tool's usability is unaffected. The jaws are sharp enough to dig into unhardened nails and the their angles provide good pivot points. Generally, if you're using a nail puller, it will be on non-finish work like framing. For finish carpentry or woodwork, pliers like the Crescent NP11 are needed to avoid destroying the workpiece.

Hammering, framing, and demolition are dangerous and can result in personal injury or damage to property. Always employ proper safety precautions like gloves, masks, and eye protection.

A Brief History Of Nails

These new nails differed from their predecessors in that they had round heads instead of square, which limited their fastening power.

When you think "advanced engineering," nails probably aren't the first thing that comes to mind. For our ancestors, though, they represented a big leap forward in building technology.

The first known use of nails dates back to ancient Egypt, sometime around 3400 B.C.E. These early models were made of bronze, but that material was soon abandoned in favor of wrought iron.

Nails make several appearances in noteworthy historical texts, as well, the most famous of these being the Bible, as they were used to hang Jesus from the cross. It's not surprising that the Romans would use nails for crucifixion, as they used them for just about everything.

The basic design and construction of these nails remained unchanged until the 19th century C.E., when cut nails hit the scene. These were made by machine, rather than forged by an iron worker, enabling factories to produce more units at a faster pace.

Despite this, nail production was still a laborious process, as these machines required workers to run them.

Wire nails were the next big innovation, and they became possible to make once breakthroughs in steel wire production occurred.

These new nails differed from their predecessors in that they had round heads instead of square, which limited their fastening power. However, by this time, thinner cuts of wood were being used in construction, and builders were able to use a tremendous amount of nails without breaking the bank, so the reduced fixing ability was a non-issue.

Another big advantage wire nails had over their forebears was their manufacturing process. Machines were developed that could make nails automatically, without needing a worker to oversee every step of the process. This eventually enabled factories to produce an incredible variety of nails, from heavy-duty construction models to thinner framing units.

So, while they may be an age-old technology, they're still incredibly important to us today, and with little alteration to their original shape. Maybe those Egyptians were on to something.

Kind of makes you want to forgive them for unleashing all those mummies on us.

How To Remove That Pesky Nail

There are few things more frustrating when doing construction than encountering a bent, broken, or headless nail. Fortunately, there are some techniques you can use to remove it without losing your sanity in the process. You should know right off the bat that this process will be considerably easier with a nail puller, but there are ways to extract a fastener even if you don't have one.

There needs to be at least a little bit of the nail exposed for this to work, or else you're going to have to either break the whole board, or learn to live with the broken fastener.

There are few things more frustrating when doing construction than encountering a bent, broken, or headless nail.

Take your puller — or the claw of your hammer — and position it so that the teeth are slightly underneath the top of the shaft. You'll want to put a piece of scrap wood around the nail where your tool will be digging in, especially if you're using a hammer. That said, you need to resign yourself to the fact that you'll almost certainly cause some damage, making these techniques unsuitable for delicate jobs or finishing work.

If the nail's too deep for you to get a good grip, you can hammer the handles of your puller in so that they sink deeper into the wood, but again, this will cause enough damage that it might not be worth it.

Once you've got a grip on the nail, pull it out. If you experience lots of resistance, try pulling a little out at a time, then re-positioning your puller further down the shaft. Many pullers also have heels that allow you to get more leverage by using them as a pivot point.

If none of this works, you can try to drive the nail out the other side by using a punch. Just put the punch over the head of the nail and hammer it through. This should only be done on thinner boards, though.

As a last resort, you can try cutting through the nail with a reciprocating saw. This is both quick and easy, but don't do it if you want to salvage the wood.

Getting nails free can be a pain, but with these techniques, you should be able to dislodge even the most sunken-in fastener. Then, with a little luck, that nail will tell all his friends that there's no running from you, and you'll never have to deal with the problem again.

The Proper Way To Hammer A Nail

The best way to deal with broken nails is not to have any in the first place, and to do that, you need to use your hammer properly.

Start off by making sure you're using the right hammer for the job. For most DIY purposes, a simple, 16-ounce claw hammer should do the trick. It's also smart to rough up the face a little bit with some sandpaper, as this will prevent glancing blows that can break or bend your nails.

If you're looking to generate power, hold your hammer at the base of the handle with a handshake-like grip.

Use your grip wisely, as well. If you're looking to generate power, hold your hammer at the base of the handle with a handshake-like grip. If you need accuracy, choke up on it closer to the head.

Hold the nail near its top using the thumb and index finger on your non-dominant hand. If you hit yourself with the hammer with your fingers at the top, it will hurt — but if you have your fingers against the board and smash the hammer into it then, you'll really teach your kids some new words.

Don't swing for the fences, either. A smooth swinging motion should produce enough momentum that the hammer does all the work for you. It shouldn't take more than a few swings to sink the nail.

Once you get proper hammering technique down, your building time should plummet — so you can spend more time in the ER with smashed fingers.