The 10 Best Manual Hand Drills

This wiki has been updated 41 times since it was first published in February of 2017. There’s no doubt electric drills are convenient, but sometimes you need enhanced precision and increased control for taking on crafts projects or working with delicate materials. That's when these manual hand drills come into their own. An agile and sustainable alternative to power tools, these practical devices come in a variety of sizes and styles to suit a range of different applications. When users buy our independently chosen editorial selections, we may earn commissions to help fund the Wiki.

Editor's Notes

November 29, 2020:

For this update, we replaced the Fiskars Rotary Craft with an updated model, the Fiskars Precision. The Fiskars Precision offers a longer handle for more control and stability while drilling, and also folds away when not in use, making it easier to store or transport.

We also replaced the AB Tools TE138, due to design complaints, and added the Kings County Tools Classic. This is a push-style drill that isn’t seen very much these days, but is still really useful. It's designed to do nearly all the work for you, you just need to place the bit on your workpiece and push the handle down.

Manual hand drills might look like they’re more of a novelty item, but they’re actually more functional than you might think. Just like how manual saws or screwdrivers can provide more accuracy and precision than their powered counterparts, manual hand drills are useful for quickly boring small and precise holes. Even the steadiest hand would have trouble drilling a small hole in a delicate wood piece with a power drill, and more than likely would make a mistake and ruin the piece. Manual hand drills are also cordless and don’t require batteries, so they’re great to have in your toolbox in the event your power drill runs out of juice.

Since they don’t require much setup, they can also be a great tool for quickly creating pilot holes in wood or drywall prior to screwing or mounting. If you’re working on larger furniture pieces, you might want to consider picking up a woodworking vise. These will keep your workpieces securely clamped in place while you drill.

All that being said, if you’re tackling large-scale projects, you’ll probably want a power drill. This collection of cordless drills should provide a nice selection to choose from.

July 09, 2019:

Added the Robert Larson 838-4000 to the list, seeing that it is one of the best manual drills on the market. It is a brace-style hand drill as opposed to egg-beater models. I prefer brace-style as they produce better and straighter holes faster. That is why the Larson and the Stanley 5044 top the list. They both have ratcheting mechanisms which just add to the appeal by allowing their use on parts of carpentry that may already be installed and cannot accommodate the tool's full sweep such as boring into corners. Also removed some redundant inclusions.

The Fiskars 85116984 and Rotary Craft made the list because they have some usefulness. However, I find their design awkward and often, a brace will be more comfortable to use, it will outperform them, and also provide many more years of service.

Like most tools, manual hand drills are dangerous and can lead to personal injury if misused or used by untrained hands. Please observe safety protocols when using any tool.

October 17, 2018:

Observed numerous complaints about the Neiko Precision’s lack of power, so I eliminated it from the list. Removed the Baigeda Precision due to a lack of availability. Noted reports that the Stanley Hand Drill’s gear gets stuck at times, so I dropped its ranking. Researched the Migiwata Twist, adding it for its affordability and effectiveness in detailed work.

A Brief History Of The Drill

On their own, they were somewhat ineffective, so craftsmen would often incorporate a coarse material like sand to aid in their functioning.

As a species, humankind if often defined by its advanced use of tools. Many of those tools can be traced back to a rudimentary root, however, the use of which is sometimes shared by members of a lower species. The drill is one such tool, as you can easily find monkeys and apes that will employ the spinning action of a good stick to bore down into a rotted out log in search of things like delicious termites.

Reaching back a couple dozen thousand years, we find evidence of homo sapiens using similar tools, often constructed from bone. These were essentially awls that would be attached to a stick of some kind and turned to bore holes into a variety of materials. On their own, they were somewhat ineffective, so craftsmen would often incorporate a coarse material like sand to aid in their functioning.

In Egypt around 6,000 years ago, the bow drill came along, which effectively translated a back and forth motion in its handle to a drilling motion in the bit. A similar type of drill also made its way into Chinese culture around this time, but it’s unclear whether they were developed independently of one another, or whether the design of one traveled from one place to the other.

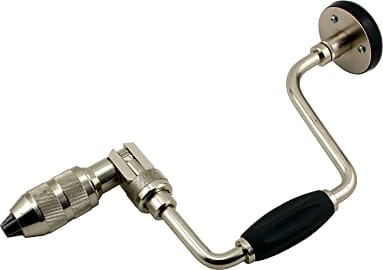

The Romans made augers popular, and these would be the last big advancement in drilling technology until the 1400s, when hand braces came along. These drills look like the letter C with a top handle and a bit jutting out vertically at the top and bottom respectively. The shape allowed for a significant increase in speed and handling compared to other designs, and this type of drill is among the more popular options for certain modern craftsmen.

The most common type of hand drill came along during the industrial revolution as a result of increases in precision manufacturing. The gear system specific to this particular hand drill could not have been reliably made previously. The simplicity of its crank mechanism made it an instant success, and its similarity to a certain kitchen tool earned it the nickname, “the egg beater drill.” It would remain the gold standard for many applications until electric drills eventually rose to prominence in the late 19th century.

Why Go Manual?

Walk down the power tool aisle of your local hardware store, and you may well wonder why anyone would turn to a manual hand drill in this day and age. There are so many powerful options out there for just about any drilling task you can imagine that there might not seem like a good reason to go manual. The argument in favor of power drills gets even more convincing when you consider how inexpensive Chinese manufacturing has made the power tool market in general.

Another important reason you might want to invest in a manual drill is to be as green as possible.

But there are still some reasons to invest in a manual hand drill that might not have occurred to you. For starters, manual drills are much easier to use when you need to apply a gentle amount of force. Most inexpensive power drills have little to no control over their speed, and if you’re working with a sensitive wood project or trying to bore a tiny hole in plaster or drywall, a power drill might overdo it.

Another important reason you might want to invest in a manual drill is to be as green as possible. Electricity has to come from somewhere, and in most cases it comes from burning coal, so that rechargeable power drill requires a carbon-producing power plant to operate. A manual drill, on the other hand, requires nothing but a little elbow grease. And if most of your drilling needs are pretty minimal, a hand drill will always be ready to go when you are — no waiting for temperamental batteries to charge. Many craftsmen prefer manual drills for this reason, as well. Relying only on the power of the person holding the drill can help instill a sense of soul into a given work piece.

Choosing A Manual Hand Drill

Your choice of manual hand drill is going to have as much to do with the kind of work you’re doing as it will with your comfort level using a certain design. As we mentioned above, these drills are most commonly used by woodworkers who need a reliable level of precision with a minimal level of power to help safeguard their work pieces against undue strain.

There’s a good chance that you’re going to need more than one type of manual hand drill to complete a given project, so don’t be shy about loading up and completing your kit in advance of setting down to work on your piece. That said, it is important to know what each type is good for, and what features to look for when evaluating them.

The other common type of hand drill you’ll see on the market today is a vertical tool known as a pin vise.

Hand braces are usually the best place to start if you’re just familiarizing yourself with the tool and you’re not actually working on anything that will become a finished product. A good hand brace with a few auger bits will allow you to drill down into scrap wood to your heart’s content, getting a feel for the manual drilling process before you advance to the larger joinery projects for which this drill is best suited.

Egg beater drills are the most practical investment for many, as they can be very gentle, and can most readily take the place of electric drills for certain projects. If you need to drill pilot holes for drywall anchors or replace a set of hinges on a cabinet door, these are the best tools for the job. Just be aware that the comfort of a unit’s handle is particularly important here, especially if you find yourself using it at an awkward angle.

The other common type of hand drill you’ll see on the market today is a vertical tool known as a pin vise. Pin vises in and of themselves are often used to hold onto materials with a tip resembling a drill’s chuck, though they aren't necessarily intended to hold drill bits or to act as drills. The models intended for drilling are specifically designed to hold drill bits, and they’re among the most gentle drilling apparatuses on the market. If you’re working with very soft woods or metals, these tools are a great way to create precision holes without damaging your materials.